1. Physical and chemical properties

| Grade |

Density (g/cm3) |

Hardness (HRA) |

TRS (N/mm2) |

Application |

| YG7 |

14.8 |

90.5 |

1800 |

Better wear-resistance than YG6, suitable for machining hard wood, original wood as well as aluminum section bar, brass rod and cast iron. |

| YG6 |

14.9 |

90.5 |

1780 |

Excellent wear Resistance and strong rigidity, suitable for the machining of cast iron, non-ferrous metal as well as bamboo and wood. |

| YG8 |

14.7 |

89 |

1900 |

Good wear Resistance, excellent anti-impact and anti-knocking properties, suitable for the manufacturing of wood working blade and machining ferrous and non-ferrous metal. |

| YG8A |

14.7 |

89.5 |

2000 |

Good wear Resistance, excellent anti-impact and anti-knocking properties, suitable for the manufacturing of wood working blade and machining ferrous and non-ferrous metal. |

| YG10X |

14.5 |

91 |

2400 |

Suitable for processing hard wood, veneer board, PCB, PVC and metals. |

| YG12C |

14.3 |

87.4 |

2500 |

Suitable for crashing the cobblestone, granite, construction materials, etc. |

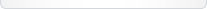

2. Product detail

| Product name |

tungsten carbide strips |

| Material |

tungsten carbide |

| Grade |

YG7, YG6, YG8, YG8A, YG10X, YG12C |

| Size/ Type |

100 long, 150 long, 200 long, 300 long, 310 long, 320 long, 330 long etc (accept customized size) |

| Surface |

Blank, simple ground, polished |

| Packing |

20kgs/ carton |

| MOQ |

5kgs (sample is also available.) |

| Delivery time |

For the normal type which we have mould, it takes 7-30 days as per your quantity after receiving the advance payment. |

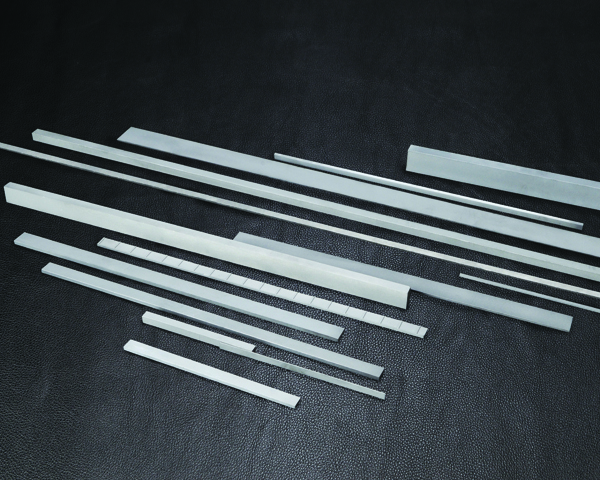

3. Application

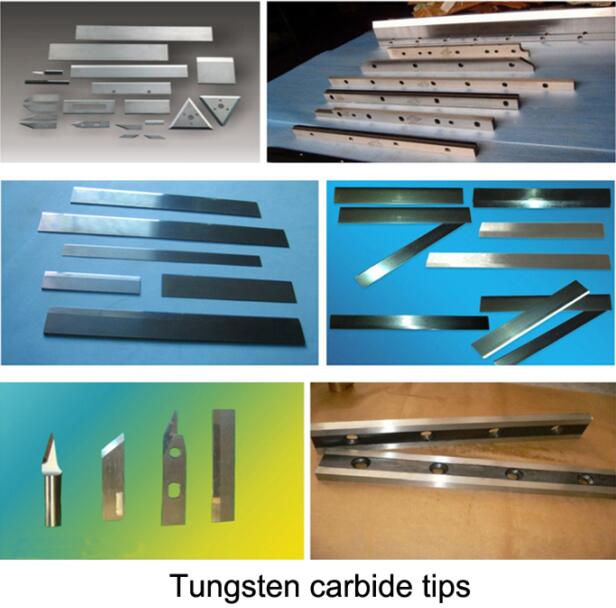

4. Production detail

|