1. Physical and chemical properties

| Grade |

Density (g/cm3) |

Hardness (HRA) |

TRS (N/mm2) |

Application |

| YG6A |

14.9 |

92 |

1750 |

Excellent wear resistance and strong rigidity,suitable for the maching of cast iron,non-ferrous metal as well as wood,bamboo. |

| YG8 |

14.7 |

89 |

1900 |

High bending strength,wear resistance lower than YG6A,used for processing blade,wear resistance parts,ect. |

| YG15 |

14 |

86.5 |

2500 |

Used for punching dies,stamping dies and wear resistance parts. |

| YG15C |

14 |

85 |

2700 |

Used for punching dies,stamping dies and wear resistance parts. |

| YG20 |

13.5 |

84 |

2750 |

High bending strength,used for step dies and other stamping dies. |

| YG20C |

13.4 |

82 |

2800 |

Dies for wear resistant or impact resistant application. |

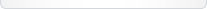

2. Product detail | Product name | tungsten carbide plates | | Material | tungsten carbide | | Grade | YG6A, YG8, YG15, YG15C,YG20, YG20C | | Size/ Type | as per customer's requirement | | Characteristic | good wear resistance | | Packing | 20kgs/ carton | | MOQ | 5kgs (sample is also available.) | | Delivery time | For the normal type which we have mould, it takes 7-30 days as per your quantity after receiving the advance payment |

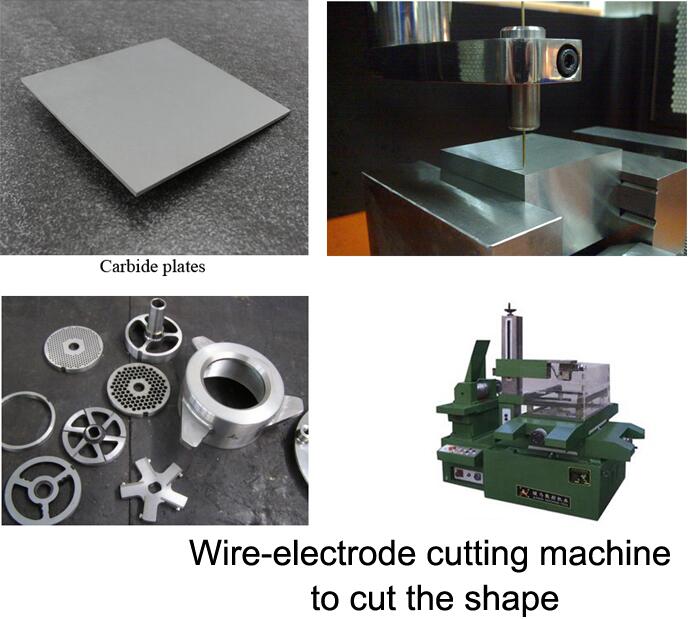

3. Application

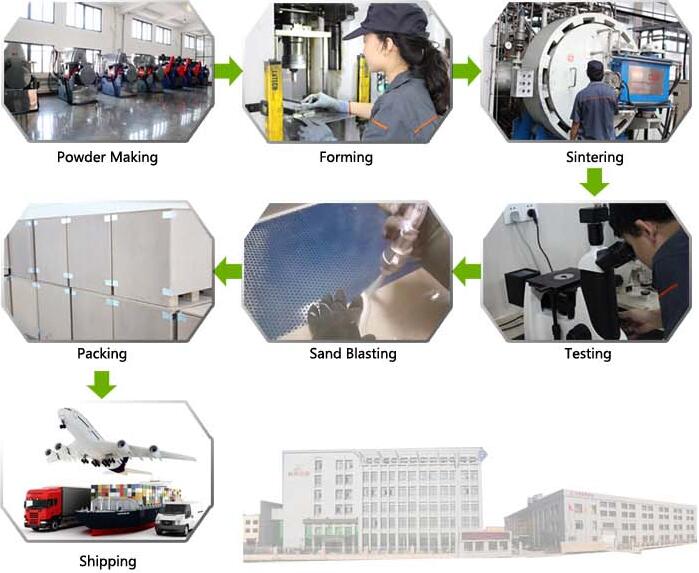

4. Production process

|