1. Physical and chemical properties | Grade | Density (g/cm3) | Hardness (HRA) | TRS (N/mm2) | Application | | YT15 | 11.1-11.6 | 91.5 | 1500 | For the semi-finishing and finishing of carbon steel,alloy steel. | | YT14 | 11.2-11.8 | 91.0 | 1550 | For the midium speed rough and semi-finishing of carbon steel,alloy steel. | | YT5 | 12.5-13.2 | 89.5 | 1600 | For the midium speed rough and semi-finishing of carbon steel,alloy steel. | | YW1 | 12.7-13.5 | 91.5 | 1800 | For the midium speed and low speed semi-finishing of heat-resisting steel,managese steel,stainless steel. | | YW2 | 12.5-13.5 | 90.5 | 1700 | For the midium speed and low speed semi-finishing and fine finishing of heat-resisting steel,managese steel,stainless steel. | | YG6X | 14.8-15.1 | 91.0 | 1800 | A fine grain grade with better wear resistance and similar strength as that of YG6 grade,suitable for cutting of chilled and alloyed refractory steels,alsosuitable for finishing of normal cast irons. | | YG6A | 14.7-15.1 | 91.5 | 1800 | A fine grain grade with excellent wear resistance and suitable for semifinishing of chilled cast iron,

non-ferrous metals and their alloys,but also suitable for semifinishing or finidhing of hardened steel and alloy steels. | | YG6 | 14.9 | 90.0 | 2000 | With better wear resisitance,and suitable for semifinishing and finishing of vast irons,non-ferrous metals and their alloys,non metallic materials at medium cutting speed. | | YG8 | 14.7 | 89.5 | 2200 | With good strength,better impact and shock resistance than that of YG6,but lower wear resistence ;suitable for

roughing of cast irons,non-ferrous metals and their alloys,as well non metallic materials at low cutting speed. |

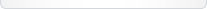

2. Product detail | Product name | tungsten carbide tips | | Material | tungsten carbide | | Grade | YT15, YT14, YT5, YW1, YW2, YG6X, YG6A, YG6, YG8 | | Size/ Type | Brazed tips as per ISO, Brazed tips as per GB, milling tips, turning inserts (accept customized size) | | Surface | Blank, polished, coating | | Packing | 20kgs/ carton | | MOQ | usually 5kgs, it also depends on the size in detail (sample is also available.) | | Delivery time | For the normal type which we have mould, it takes 7-30 days as per your quantity after receiving the advance payment |

3. Application

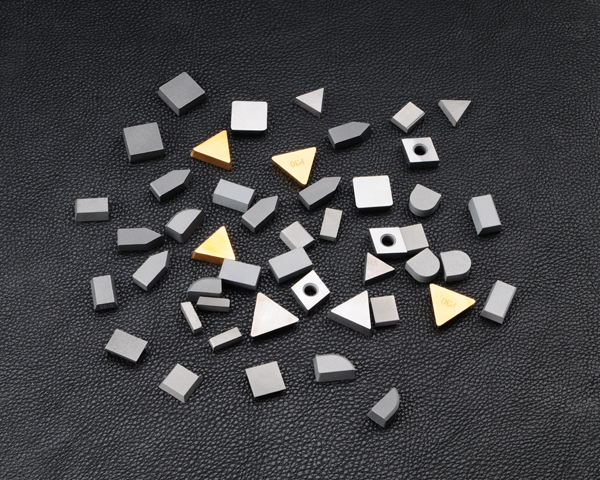

4. Production process

|